Seamless steel gas cylinders are a crucial component of various industries, serving as vessels for storing and transporting compressed gases safely and efficiently. These cylinders play a pivotal role in applications ranging from medical gases to industrial processes and are subject to rigorous international standards to ensure their reliability and safety. One such standard is EN ISO 9809-1, which sets the guidelines for seamless steel gas cylinders.

The Significance of Seamless Steel Gas Cylinders

Seamless steel gas cylinders are indispensable tools for the storage and transportation of various gases, including but not limited to oxygen, nitrogen, hydrogen, and argon. They find applications in a wide range of sectors, such as healthcare, metallurgy, aerospace, and industrial manufacturing. The significance of seamless steel gas cylinders lies in their ability to safely contain highly compressed gases, making these gases readily available for use in critical processes and applications. Below are some key areas where these cylinders play a pivotal role:

Medical Applications

In the field of healthcare, seamless steel gas cylinders are employed for the storage and delivery of medical gases like oxygen and nitrous oxide. These gases are vital for patient care in hospitals, clinics, and emergency medical services. The high-pressure storage capability of seamless steel cylinders ensures a constant and reliable supply of medical gases, which is essential for various medical procedures, including anesthesia and respiratory therapy.

Industrial and Manufacturing Processes

Industries such as welding, metal fabrication, and chemical processing rely on seamless steel gas cylinders to provide a consistent source of gases needed for their operations. Welders, for instance, use cylinders filled with gases like acetylene and argon to create high-quality welds, while manufacturers depend on them for processes like heat treatment and material testing.

Aerospace and Aviation

Aerospace and aviation industries use

EN ISO 9809-1 gas cylinders in various applications, including aircraft landing gear systems, hydraulic systems, and oxygen supply for aircraft crews. The durability and pressure resistance of these cylinders are critical to ensuring the safety and performance of aircraft.

Specialty Gases

In laboratories and research facilities, specialty gases with specific purity levels are often stored in seamless steel gas cylinders. These gases are essential for scientific experiments, calibration procedures, and analytical measurements. The high-quality construction of these cylinders prevents contamination and ensures the integrity of the stored gases.

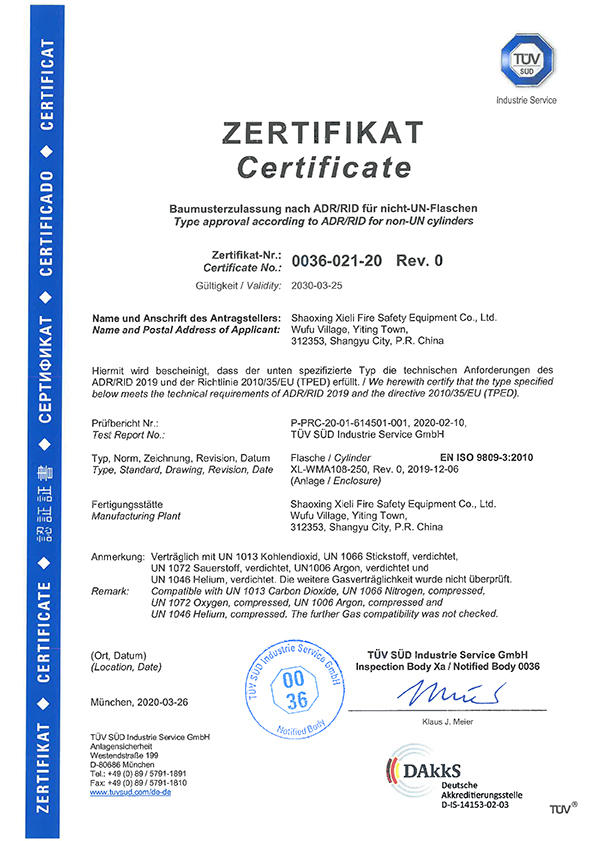

EN ISO 9809-1: The Standard for Seamless Steel Gas Cylinders

EN ISO 9809-1 is a prominent international standard that lays down the specifications and requirements for seamless steel gas cylinders. Developed by the European Committee for Standardization (CEN) in conjunction with the International Organization for Standardization (ISO), this standard is recognized and adhered to worldwide. EN ISO 9809-1 encompasses several critical aspects of seamless steel gas cylinders, including design, manufacturing, inspection, and testing.

Design Specifications

EN ISO 9809-1 provides comprehensive guidelines for the design of seamless steel gas cylinders. This includes specifying the materials to be used, the cylinder's shape and dimensions, and the design pressure, which is the maximum pressure the cylinder can safely withstand. The standard also defines the valve and thread specifications for gas cylinders to ensure compatibility with various gas distribution systems.

The design specifications outlined in EN ISO 9809-1 are crucial for ensuring the structural integrity and safety of gas cylinders, especially when they are subjected to high pressures. Compliance with these specifications is essential to prevent leaks, ruptures, and other potentially hazardous incidents.

Manufacturing Processes

To meet the requirements of EN ISO 9809-1, seamless steel gas cylinders must undergo stringent manufacturing processes. These processes are designed to ensure the cylinders' integrity and performance throughout their operational life. Key manufacturing processes include:

Cylinder Forming: The cylindrical shell of the gas cylinder is formed from high-quality steel sheets using specialized processes such as hot spinning or deep drawing. The choice of steel and the manufacturing techniques must adhere to the standard's requirements.

Heat Treatment: Heat treatment processes are applied to improve the mechanical properties of the steel, enhancing its strength and toughness. This ensures that the cylinder can withstand the internal pressure generated by the compressed gas.

Neck and Valve Installation: The cylinder's neck, which houses the valve, is threaded and installed according to the standard's specifications. This is a critical step to ensure a secure seal between the cylinder and the valve.

Internal Cleaning: The interior of the cylinder is thoroughly cleaned to remove contaminants and debris that could react with or contaminate the stored gas.

Hydrostatic Testing: Every gas cylinder must undergo a hydrostatic pressure test to verify its structural integrity. During this test, the cylinder is pressurized with water, and its expansion is measured to ensure it meets the standard's requirements.

Inspection and Testing

EN ISO 9809-1 mandates rigorous inspection and testing procedures to verify that seamless steel gas cylinders meet the standard's specifications. These procedures are conducted at various stages of manufacturing and include:

Visual Inspection: Visual inspection is performed to identify any visible defects in the cylinder's exterior, such as dents, scratches, or signs of corrosion.

Ultrasonic Testing: Ultrasonic testing is used to detect internal flaws, such as cracks or voids, that may compromise the cylinder's integrity.

Pressure Testing: Pressure testing, which includes hydrostatic and pneumatic tests, is conducted to evaluate the cylinder's ability to withstand internal pressure safely.

Leak Testing: Leak testing is performed to ensure that the cylinder and its valve do not have any leaks that could result in gas loss.

Thread Inspection: Threading on the cylinder neck and valve is inspected to ensure proper engagement and sealing.

Compliance with these inspection and testing requirements is essential to guarantee the safety and reliability of seamless steel gas cylinders. Cylinders that do not pass these tests are rejected to prevent potential hazards.

Compliance with International Regulations

EN ISO 9809-1 harmonizes with various international regulations and standards related to gas cylinders. It ensures that seamless steel gas cylinders manufactured according to its specifications can be safely transported, stored, and used in different countries without encountering significant regulatory barriers. Compliance with international regulations is vital for seamless trade and the safe handling of gas cylinders on a global scale.

中文简体

中文简体 عربى

عربى